Protecting Life, Safeguarding Asset

GASENSOR is dedicated to safety monitoring gas and flame in hazardous area and environment. Our company has rich experience in designing and manufacturing gas and flame detectors, and has professional teams which can provide solutions, consultations and equipment supply services

GASENSOR

is a Singapore high-tech, professionally managed manufacturing company established in 2013 that is committed to the continuous research and development of gas detectors and fire detection system of environmental safety monitoring products, with rich experience in the applications of fire and gas monitoring products to protect people’s lives, health and assets.

GASENSOR PRODUCTS

FLAME DETECTOR

Quad IR Flame Detection

Ultra FL800 Series

The Model Ultra FL800 is an advanced multi-spectrum infrared (MSIR) flame detector based on the Artificial Intelligence Recognition Technology.

The Ultra FL800 is provided with wider field of view and further detection range because of a multi-spectrum infrared sensor array with a sophisticated BP Neural Network Technology system.

The Ultra FL800 can see typical fires such as those produced by alcohol, heptane, gasoline, jet fuels and hydrocarbons. In addition, it can also detect and identify non-flame signals, for example arc-welding, hot objects, sunlight and moonlight. The Ultra FL800 is designed to only alarm for the conditions that caused by real flame signal, and highly immune to false alarms for non-flame signals.

The Ultra FL800’s electronics are housed in a stainless steel explosion-proof enclosure. The detector is available with the following output configurations:

• 4-20mA stepped output

• Dual RS485 communications

• HART communication

• Warning, alarm and fault relays

GAS DETECTOR

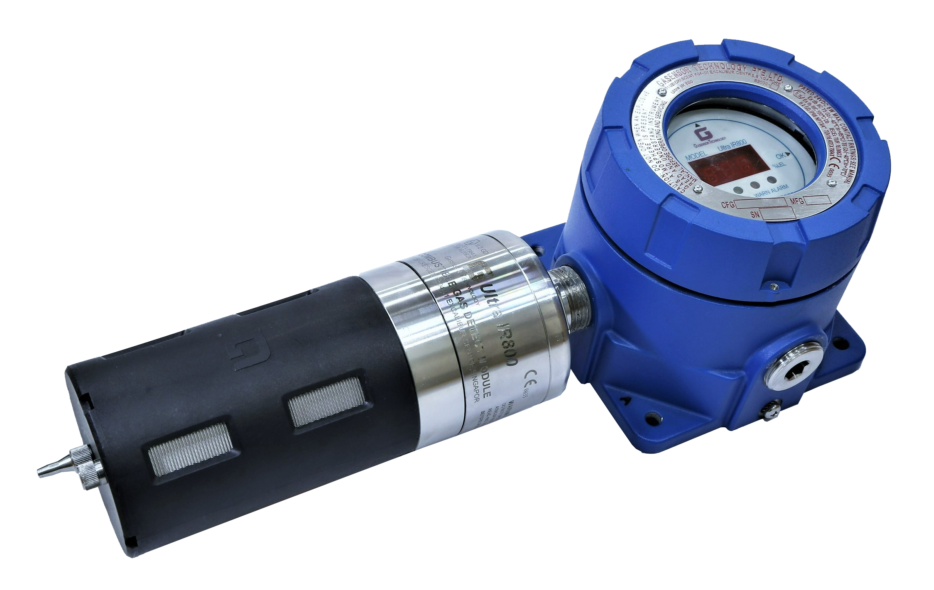

Explosion Proof Type Combustible Gas Detector (Point IR)

Ultra IR800 Series

The Model Ultra IR800 Infrared (IR) Point Detector is a microprocessor-based combustible gas detector that continuously monitors combustible gases in lower explosive limit (LEL) range

Ultra IR800 is housed in an explosion-proof enclosure complete with status display, which consists of three high-brightness nixie tubes and four status indicators for gas concentration readings and status conditions

This IR point detector provides various output interfaces which includes 4-20mA current output, three sets of Normally Open Contact for Warning/Alarm/Fault status, two sets of communication interfaces for RS485 and HART interfaces

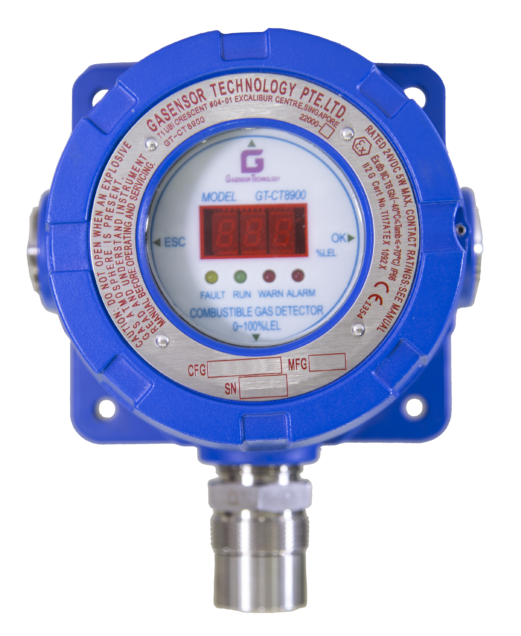

Explosion Proof Type Combustible Gas Detector (Catalytic)

GT-CT8900

Model GT-CT8900, Fixed type Catalytic combustible gas sensor, engineered specifically for detecting combustible gas (Methane) and vapor

The sensor is housed together in an explosion-proof enclosure complete with status display, which consists of three high-brightness nixie tubes and four status indicators for gas concentration readings and status conditions

In addition, a sensor life indication function is provided for ease of maintenance and improves instrument reliability

GT-CT8900 provides various output interfaces which includes 4-20 mA current output, three sets of Normally Open Contacts for Warning/Alarm/Fault status, two sets of communication interfaces for RS485 and HART interfaces

Explosion Proof Type Oxygen and Toxic Gas Detector

GQ-CE8900

A new generation of intelligent Toxic Gas Detector, Model GQ-CE8900, which adopts the smart sensor technology and features a safety function automatically identifies and determines the remaining usage life of the sensor

This easy-to-use GQ-CE8900 also features the detection of different gas concentrations by simply replacing the sensor and re-calibrating accordingly. It also provides a real-time fault diagnosis to ensure safe and effective operations

GQ-CE8900 can monitor toxic gases presence consistently and continuously in installation sites. This Toxic Gas Detector has a standard 4-20mA current output and three sets of Normally Open Contact relays for Warning/Alarm/Fault

These features make it easy for the detector to connect to various control units. In addition, there are dual redundant Modbus and HART communication interfaces for data transfer to PLC, DCS, PC, etc

.

SOLUTION

Controller

T200

The T200 gas monitor (wall mounted) is a microprocessor based intelligent controller with outstanding performance and complete alarm function

The T200, together with our combustible gas , toxic gas and flame detectors like GT-CT8900, Ultra IR800 ,GQ-CE8900 and Ultra FL800, etc., can form a fire or gas detection & alarm system to continuously monitor leakage of combustible or toxic gases in the environment and to prevent fires

The T200 monitor consists of a wall-mounted chassis (including the register card) and control cards. The control card can supply power to the detector and receive the signal that is proportional to the gas concentration from the detector

The control card has a LED that will digitally display concentrations of target gases

It also outputs audible & visual and contact alarm signals when concentrations exceed the set point. The control card also has a 4-20mA analog signal output that is related to the field concentration and then the register card shall output relevant RS485 signals

The T200 gas monitor features a multichannel and plug-in structure. Both 8-channel and 16-channel(loop) models are available

Customized Solution

Gasensor Monitor

Customized local monitoring system for safe area oxygen, toxic or combustible gas concentration monitoring. The Gasensor Monitor can be implemented for light industry and commercial applications. For example, it can be used to monitor oxygen deficiency in chemical laboratory room

Local Audible (Buzzer) and Visible Alarm within interior and external of the safe area; it requires minimum maintenance with built in non-instrusive calibration procedure, and the gas sensor can be replaced without recycling power

Please Contact Us for more information

Customized Solution

Gas sampling system - Sample Draw System

GS900

The GS900 gas sample draw system is designed to continuously extract of ambient air mixtures from sampling point/s. Gas Condition Process is put in place to condition the sampled gas suitable for gas detection measurement to take place

The sampled gas is then exhaust into downstream vent point or directly to the atmospheric air

GS900 gas sample system ensure a high sample integrity and optimal response time. It is recommended over direct placement of sensor at confined applications with difficult maintenance access or limited installation space

It is also recommended to provide gas sample draw system in extreme harsh environment, (i.e. high ambient temperature, high dust load, high humidity, corrosive, etc ) which could impair the sensor

Please Contact Us for more information

Customized Solution

Gas sampling system

Gas monitoring throughout coal power application

Due to high coal dust load and temperature limitation for Electrochemical cell sensor technology, it is not possible to provide in-situ point detection.

It is recommended to implement Gas Sampling System over In-situ Detection to monitor Carbon monoxide leakage with the below consideration

1. Periodic sampling and purging for each sample system

• PLC Controller to perform automatic switching

• Implement 1-5 rule to sample and purging

2. Tailor made Filtration Conditioning system to remove coil dust and moisture content

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton