BUSINESS & INTELLIGENT AUTOMATION SYSTEM

Providing wide range of professional services to meet your needs. Every single service we provide with a smile to your highest level of satisfaction.

Power your factory with AI & IIoT

Transform your factory to the Industry 4.0 standard

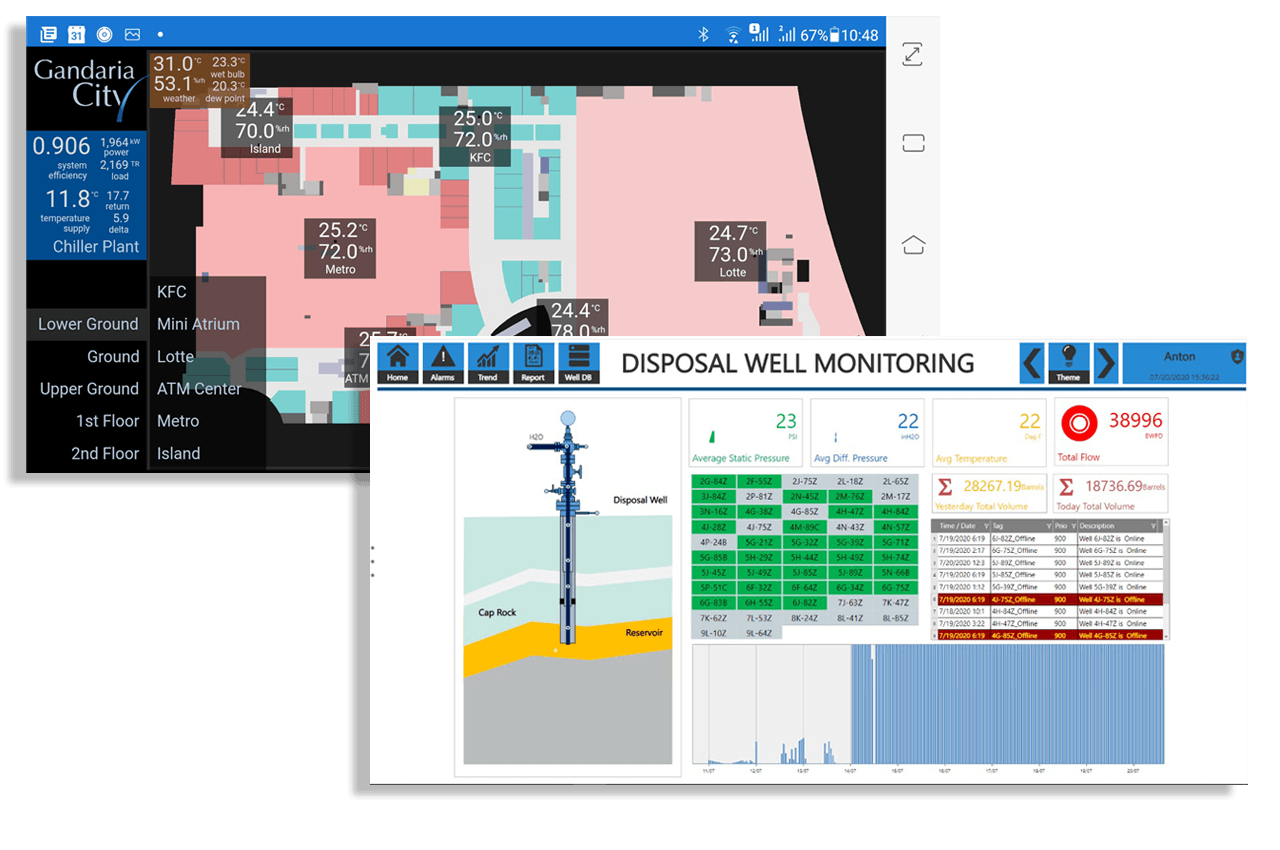

Managing your smart factory would be as easy and enjoyable like driving our plant operations and business like a car combining with various online measurements, analytics, diagnostics and alerts in the dashboard shown in IIoT.

Run your business and make decision

anywhere you go

In this era of Industrial Internet of Things (Industrial Iot) where software, machine and equipment are seamlessly connected and create wealth of data, analytics, diagnostics and alerts. Visualize the most important Key Performance Indicators (KPI) of any part of your business at your finger tips.

Our system would assist Management and Operators from multi Disciplines towards the right direction to accurately make decisions based on real time data, information, analysis and diagnostics. The AI system will provide prediction based on the previous experience and yet you would still be able to control the factory based on your own decisions.

Get your production data feeds in real time.

Visible to authorized Users from any gadget, anywhere, anytime!

KPI

List all Key Performance Indicators that will help you to

make better and faster decision for your business.

Managed your team efficiently and monitor

the perfomance closely

OEE Analysis

Overall Equipment Effectiveness

Watch how your operation utilize its time, material and production compared to its full potential. Measure the availability, performance and quality.

Gain important insights on how to systematically improved your manufacturing process.

No more waiting for reports!

Fault Detection & Diagnostics (FDD)

Identifies the anomalies performance of the critical equipments in real time.

Early detection and deliver notifications to operator and detailing the root cause and how to resolve the issue.

Various Alerts

Send alerts and notification in any part of your production process and notify respective departments for immediate attention and action.

Take a full control of your business anywhere you go.

Human Machine Interface

Operators in manufacturing environments often have oversight over many pieces of equipment. HMI and SCADA (supervisory control and data acquisition) solutions allow them to precisely monitor, control, and visualize every aspect of their operations in a centralized manner. With a quick glance, operators know what's important and the right actions to drive increased efficiency and reduced costs. It's a combination between software and hardware elements that make possible for the management to fetch the datas.

HMI/SCADA collects data from RTUs (Remote Terminal Units), PLCs (Programmable Logic Controllers), and other control devices such as flow meters and temperature controllers, and presents these to an operator using a Human Machine Interface (HMI.) The HMI allows the operator to see what is going on in real time, including custom mimic displays, alarms, trends, etc., to make decisions to adjust any machine controls or settings